-40%

Sawmill Plans to build a heavy duty band sawmill to cut wood for lumber

$ 17.41

- Description

- Size Guide

Description

Sawmill Plans to build a heavy duty band sawmill to cut wood for lumberNOTE!!! These plans are DIGITAL ONLY which you must download to your PC. This is a zipped Download of many files in .PDF Format!

If you purchase the sawmill plans, you will receive an eBay message with step by step instructions on how to download a copy of the sawmill plans to your Windows personal computer or MAC computer

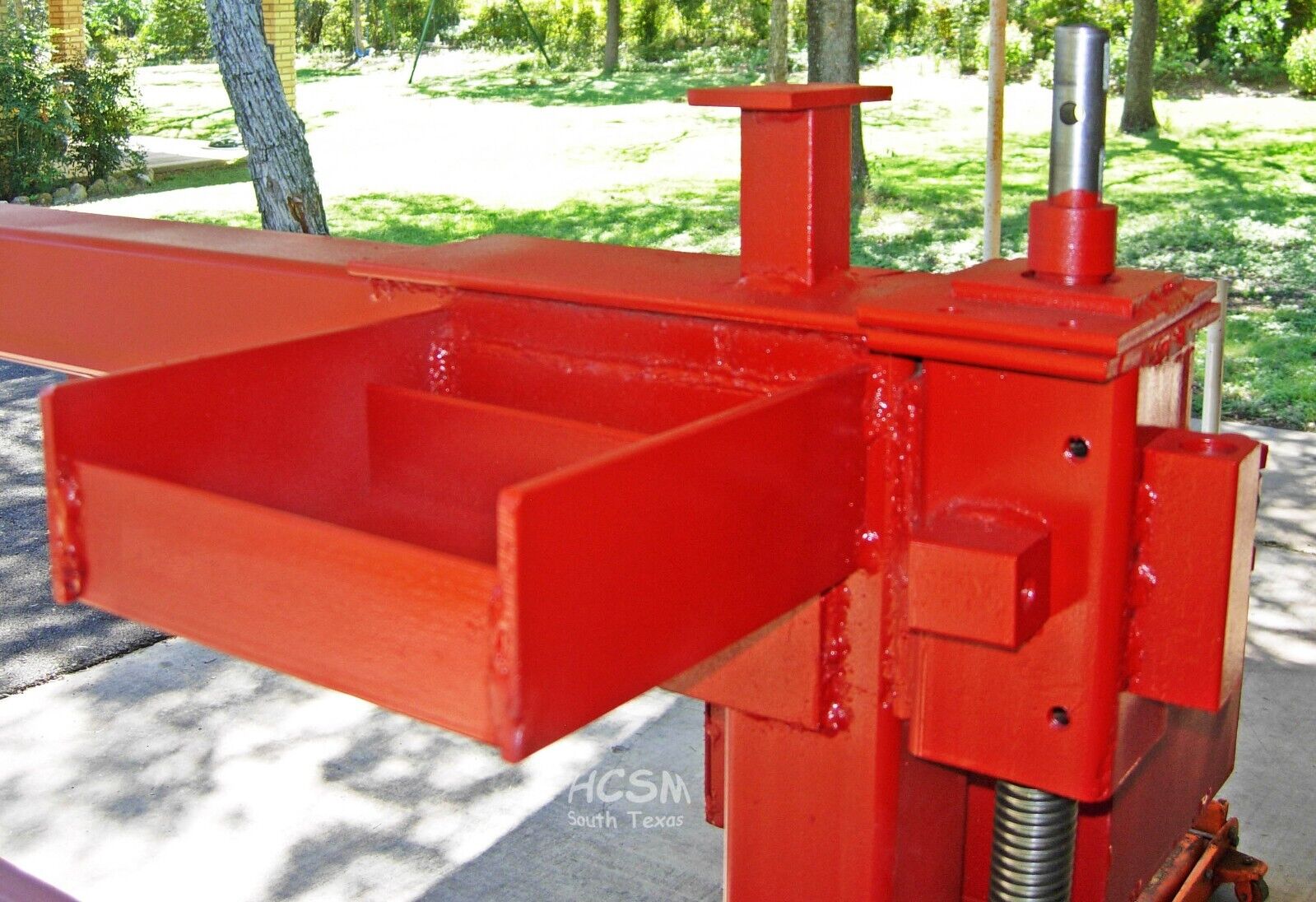

All the details you need to build your own wide slabber bandsaw mill capable of handlingand cutting a 76″ diameter log.

Heavy duty build construction for smooth and stable cuts.

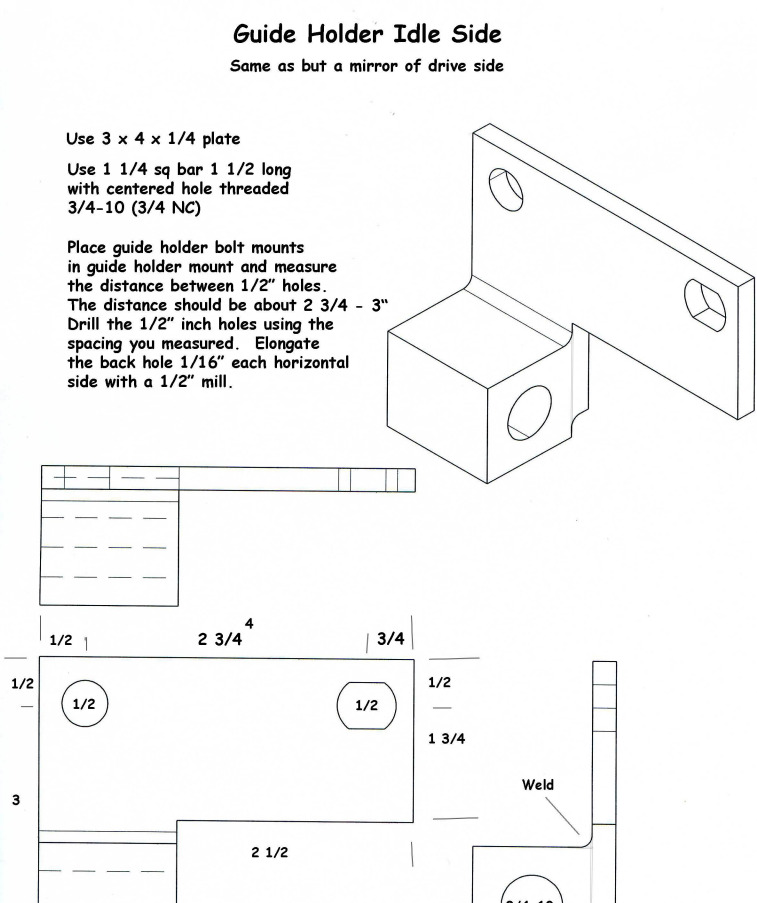

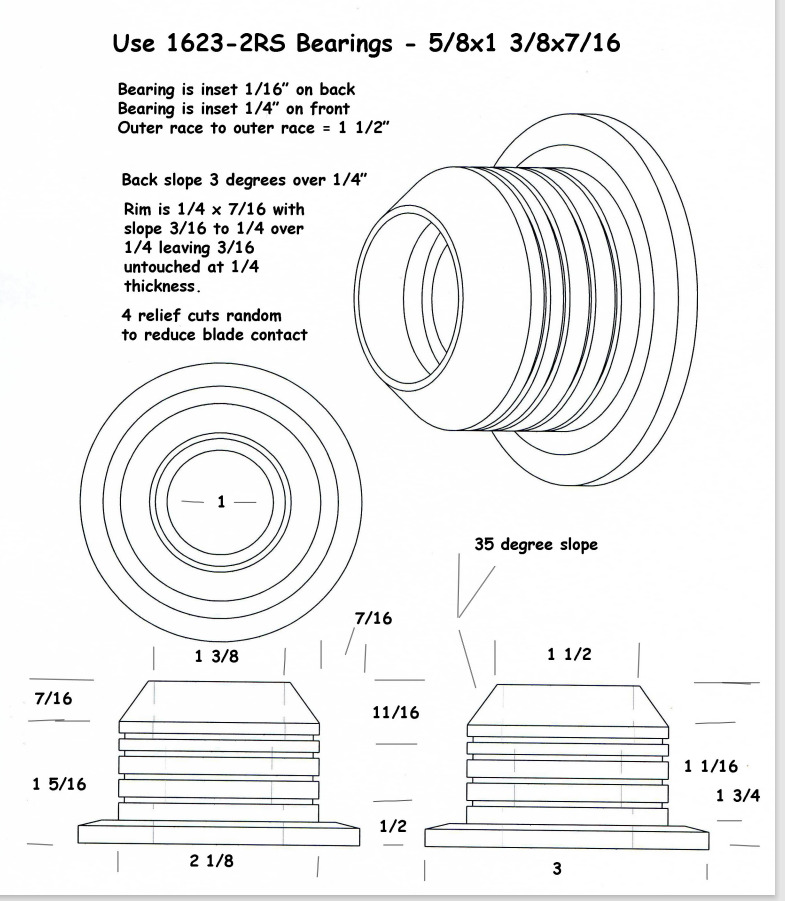

The plans consist of step by step written dialogue, 60+ measured drawings (parts and assemblies), and 3D PDFs of each part and many partial assemblies.

Using the 3D PDFs feature found in the current release of Adobe Reader, you can rotate and view every part from every angle.

The drawing and 3D files were created using the same software used to create input for 3D printers, so the detail is very good.

There are also a lot of pictures and some videos.

So whether you need a lot of handholding or if you see it you can build it, the plans are designed to meet your needs.

You will likely find that you only need a few of the drawings,because the sawmill is far simpler to build than it looks.

Every part not found in your local hardware store is drawn and viewable in 3D so that understanding what it does and how it works should quickly become understood.

The demonstration sawmill was built to cut Mesquite, a very hard wood, so it will make short order of any kind of wood you want to saw.

Basically, it utilizes a very simple frame and track.

How good of a sawmill do you want to build? As designed, properly aligned and with a sharp blade, this sawmill will cut a plank 1/8” thick, 24”wide and 8’ long 20” above the track repeatedly in hardwood. "SK" bushings with 3 adjustment bolts and 2" diameter shafts are used with clones of the original Browning industrial pulleys available reasonably from a national distributor. Ever try to align something with 2 bolts on a weak shaft that gets stressed.

It has all of the little things that make it a great saw. A sawmill works best when everything is heavy duty and oversize and you use a sharp blade. This sawmill has the qualities of the best available sawmills without the stuff most people do not need. The frame is made from 3” x 3” x 3/16” tubing with a lot of ¼” plate structural supports,so whether you saw with 9HP or 30HP, it will be stable when the blade is 28”above the track and you are cutting at full power.

The demonstration sawmill was built to cut Mesquite, a very hard wood, so it will make short order of any kind of wood you want to saw. Basically, it utilizes a very simple frame and track. It has all of the little things that make it a great saw. A sawmill works best when everything is heavy duty and oversize and you use a sharp blade. This sawmill has the qualities of the best available sawmills without the stuff most people do not need. The frame is made from 3” x 3” x 3/16” tubing with a lot of ¼” plate structural supports,so whether you saw with 9HP or 30HP, it will be stable when the blade is 28”above the track and you are cutting at full power.

The saw blade is raised with a 0 utility winch twisting 1¼” diameter acme thread rods, so you raise or lower by pressing a rocker switch which comes with the winch. The acme rods greatly improve saw cutting accuracy. You can instead use a cable lift system to save a little money and effort. I provide a reasonable cost source for the acme rods. The saw cuts easily with as little as the use of one hand because it rides on 3” dual ball bearing wheels which you can build or buy readily and reasonably from gate suppliers or eBay. The drawings show a new blade guide design using a 2” roller and a ball bearings. The guides are easily adjusted up/down, in/out, and tilt. Because they are so rugged, they will keep their alignment. The design greatly reduces blade stress and heat.

Cost is a big issue and you should be able to saw your first log for as little as ,500 using all new components. The cost is based on using the suggested component suppliers. If you follow the provided suggestions, you will likely be able to reduce that cost a lot. A little creative recycle effort will dramatically reduce your cost. Much of the cost is steel and the engine and it's snowmobile clutch. As with pressing a switch to raise/lower your blade, you will find that having a centrifugal clutch is a great feature to have.

*

.

If you purchase the sawmill plans, you will receive an eBay message with step by step instructions on how to download a copy of the sawmill plans to your Windows personal computer or MAC computer